Purchasing Strategy – A New Approach

Keith Jones BSc. MBA

Building on a 35-year career in the chemical industry where he worked in areas ranging from R&D, Manufacturing, and Purchasing, through to Supply Chain, Finance and Project Management, Keith established Cadnant Consulting specialising in inventory management, project data analysis and forecasting.

Connect with Keith through www.cadnantconsulting.com

This article is based on the Purchasing Strategy described in Keith’s book ‘Inventory Management for Competitive Advantage: Including a Practical and Effective Purchasing Strategy for Managers’. Published by Routledge (Tailor & Francis Group) in March, 2020.

Drawing on his breadth of experience, Keith proposes a new approach to the development of a purchasing strategy.

Introduction

When a business strategy is developed, it is essential that every function within the organisation is aligned to that strategy and that every individual understands how their function connects to and supports the overall business strategy.

As many organisations will know, it is no easy task to ensure that every function is ‘pointing in the same direction’ when it comes to strategy. Whilst each function can have its’ own set of conflicting objectives, Purchasing can never get away from ‘cost’ being an over-riding factor in the development of their strategy given the potential impact on profitability.

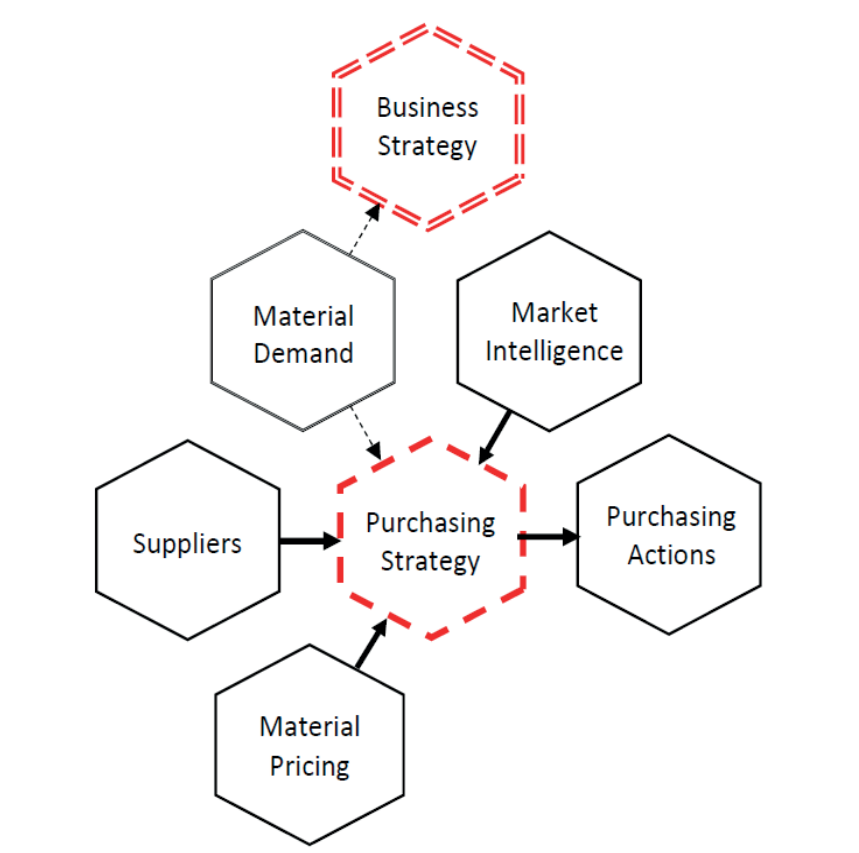

Figure 1 shows how Purchasing Strategy can sometimes be disconnected from the Business Strategy.

Disconnected strategies can have unintended consequences develop despite the best of intentions. These can invariably impact both the supply of raw materials and relationships with suppliers. Having an effective and completely aligned Purchasing Strategy avoids these issues.

Of course, ensuring alignment is not easy and there is little available at a practical level that will enable purchasing professionals to translate their business’s strategy into an aligned Purchasing Strategy with associated clear and coherent actions.

Figure 1: Business and Purchasing Strategy Disconnected

When developing corporate strategies, organisations can draw on many tools to help them in the process. These include Michael Porter’s Value Chain Analysis (1) and Five Forces, SWOT Analysis, BCG Matrix2 and so on.

The value of these tools is not in doubt but ensuring that all functions are aligned to the strategy is no easy task and this is no less true for purchasing strategy. However, when it comes to purchasing strategies, structured approaches are few and far between. Indeed, the main method used for the development of a purchasing strategy is often based on a pareto analysis of cost. In other words, purchasing staff will focus on the 20% of materials that make up 80% of costs.

Whilst this approach is of importance, it does not necessarily follow that corporate and purchasing strategies are completely aligned. Small, seemingly insignificant purchases can easily be forgotten when, on closer inspection they are of equal importance in terms of their relation to strategy.

Why does it matter?

The longer a disconnect exists between strategies, the more likely it is that an ever-increasing gap will appear between functional and business strategies.

In addition to pricing, there are other factors that Purchasing need to take account of when procuring materials and services for their organisation. For example:

- Variability in supply

- Service level

- Continuity of supply

- Supplier relationships

- Procurement cost control

Managing factors such as those shown above needs to be done in a structured way. The question is how?

A New Approach

There are two key factors to consider when developing an aligned purchasing strategy – the significance of a material or service in relation to the strategy and the risks associated with the procurement of those same materials or services.

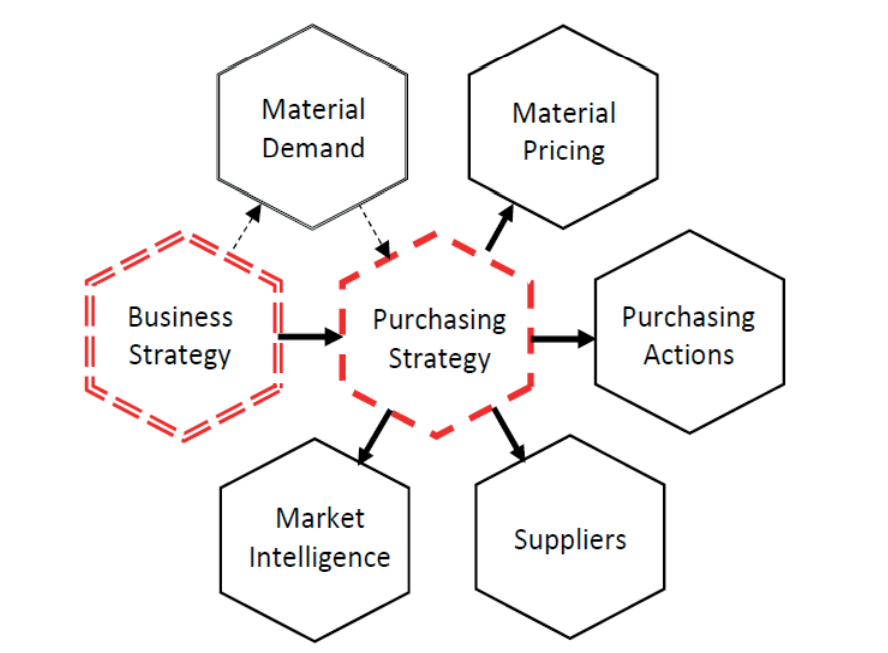

Classifying a material or service in terms of its’ strategic significance is the first step in ensuring that the business strategy is directly determining a key factor in the development of a purchasing strategy – see Figure 2.

Figure 2: Business and Purchasing Strategy Directly Connected

Procurement risk is effectively a method of determining the risk exposure that an organisation has in relation to each material or service that it purchases. Aspects that need to be considered include:

- Sourcing risk

- Price control

- Quality of supply

- Flexibility of supply

- Reliability of service

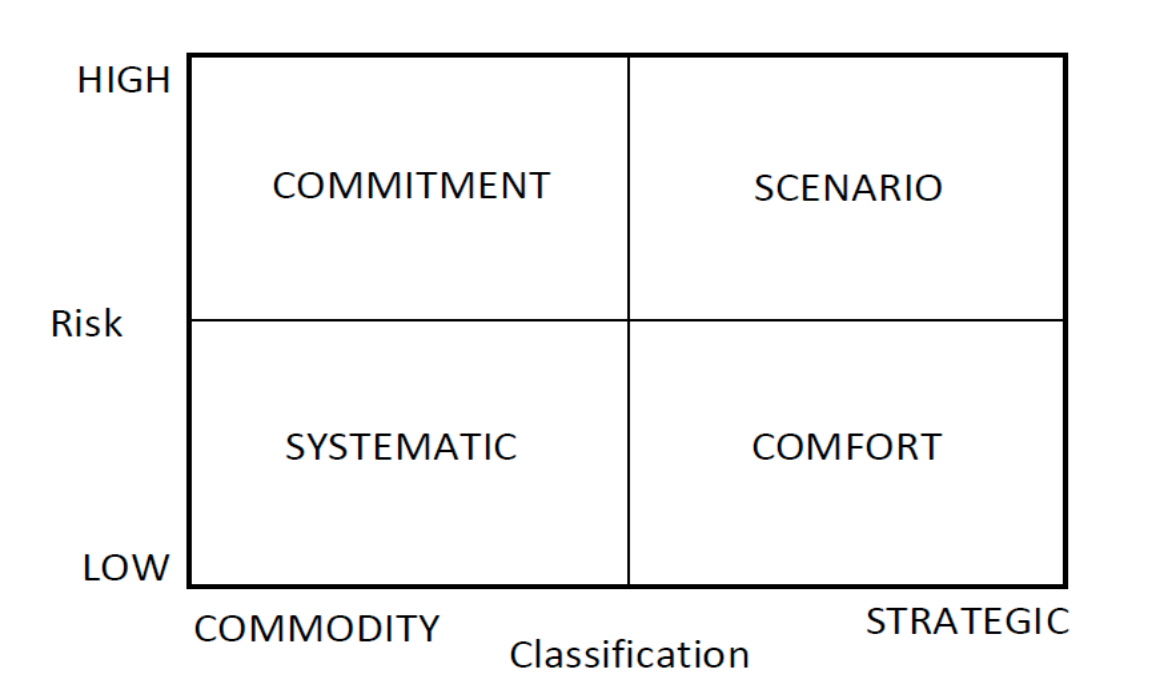

Combining strategic significance and procurement risk enables users locate materials and services in a 2 x 2 matrix – see Figure 3.

Figure 3 – Profile Strategies

Each quadrant has a specific set of recommended actions that not only enable users to adopt a structured approach to the procurement of materials and services, but also, through the incorporation of profit impact, a means of prioritising their actions.

Over time, users will also be able to see how materials transition between quadrants as strategies and procurement factors change. Over the medium term this is a useful means of anticipating changes in procurement risk and classification, putting control firmly in the hands of purchasing functions, whilst at the same time ensuring direct alignment with business strategies.

Summary

Developing a purchasing strategy that is directly connected to the organisation’s overall strategy is vital and enables an organisation to better appreciate the way that each and every individual raw material should be dealt with – and not just those that have the greatest impact on profit.

Having a structured approach will provide clarity and guidance in developing a relationship with a supplier and ensure that they are working with you to deliver your goals and be able to adapt as your need change over time.

Adopting the approach discussed is a departure from many purchasing strategies in that some of the emphasis is shifted away from cost by asking the question – “How does each and every raw material relate to the business strategy?”

The key aspect is that, as should be the case with all other functions, the Purchasing Strategy will be aligned to the business strategy and that all activities will have a clearer purpose and individual staff members will be better able to relate their approach to the organisation’s goals.

Of course, as time passes, the strategy can easily be reviewed and an organisatrespond to changing circumstances and how this might impact not only the business strategy, but also the Purchasing Strategy. Of course, working with colleagues in R&D, Marketing, Production and Sales will ensure that many of the changes can be anticipated and appropriate planning can take place where new strategies are required.

© Keith Jones 2020

References

- (1) Porter, M.E. (1985). Competitive Advantage – Creating and sustaining superior performance. New York: The Free Press 2 Henderson, B

Would you like to contribute an article towards our Professional Knowledge Bank? Find out more.